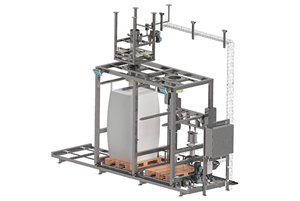

Big Bag Filling

Big bag filling stations are used for handling and weighing powders and granulates. Tekfa has many years of experience in big bag filling systems (also known as FIBC filling stations) and has delivered units to all industries, including the food industry, chemical industry, and pharmaceutical sector. Over the years, Tekfa has adapted its filling stations to numerous special requirements, meaning that the company has an extensive archive of filling stations tailored to meet all needs and specifications. A filling station essentially consists of a series of standard modules, which can be supplemented with various accessories.

Big bags (or FIBC systems) can be manufactured as standalone units or as combinations of multiple units, where, for example, in continuous production, big bags are alternately filled—first in one unit, then in the other. The filling stations can be designed as dust-tight units and accommodate various big bag sizes.

Typical Parameters:

- Open or dust-tight filling

- Mobile or stationary unit

- Vibrating base

- Approved weighing (if the big bag is to be sold based on its weight)

- HMI (control panel) and integration with factory management systems

- Easy cleaning and maintenance

- Steel options: AISI 316L, AISI 304, or carbon steel (painted)

- Ergonomic, automated solutions available—contact us for further information

- Easy interchangeability between filling heads, e.g., switching between big bag filling and tote bin filling

A Simple Standard Big Bag Filling Station Includes:

Dust-Tight Filling

The filling spout of the big bag is wrapped around an inflatable collar, which inflates, tightens, and seals off to prevent dust from escaping. A breathing filter ensures excess air can be released.

Weighing

Equipped with 4 load cells, 1 junction box, and 1 weighing instrument. TEKFA’s standard comprises OIML-certified units, where weighing can be approved for commercial transactions. Additionally, an antistatic flexible transition is integrated at the inlet.

Vibrating Base Frame

Helps distribute the powder evenly within the big bag.

Integrated Control Panel with Air Control and Full Indicator Lamp

Alternatively, users can connect their own weighing instrument and pneumatic control panel to their system.

Inflation of the Big Bag Before Filling

This prevents folds in the big bag from getting trapped and causing obstructions.

Stainless Steel AISI 304 as Standard

Acid-resistant stainless steel, AISI 316, is not standard but can be supplied. However, delivery time depends on Tekfa’s workshop workload. Big bag filling stations in painted carbon steel are produced by subcontractors.